Gold mining was, without a doubt, a profitable business, but it wasn’t an easy business to be in, especially in the early days. The miners-turned-innovators had to figure out ways to speed work up in order to make a profit. Gold is a tricky metal to find and mine, as are most precious metals. One thing that was needed, especially in underground mining, was a way to get the ore out of the mine, and the tools and workers into the mine. It is a waste of time to have workers walking long distances into the mines., their tools are heavy, and carrying all that in makes for slow going…if the miners

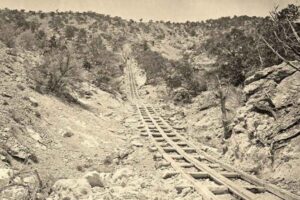

Gold mining was, without a doubt, a profitable business, but it wasn’t an easy business to be in, especially in the early days. The miners-turned-innovators had to figure out ways to speed work up in order to make a profit. Gold is a tricky metal to find and mine, as are most precious metals. One thing that was needed, especially in underground mining, was a way to get the ore out of the mine, and the tools and workers into the mine. It is a waste of time to have workers walking long distances into the mines., their tools are heavy, and carrying all that in makes for slow going…if the miners  are walking anyway. A mine railway, also called mine railroad or sometimes pit railway, is a railway constructed to carry materials and workers in and out of a mine. Few people would remember, but the mix of heavy and bulky materials which had to be hauled into and out of mines gave rise to the first several generations of railways. The first rails, like this one, photographed in Illinois by Timothy O’Sullivan leading to a gold mine, was made of wooden rails. Eventually they added protective iron, steam locomotion by fixed engines and the earliest

are walking anyway. A mine railway, also called mine railroad or sometimes pit railway, is a railway constructed to carry materials and workers in and out of a mine. Few people would remember, but the mix of heavy and bulky materials which had to be hauled into and out of mines gave rise to the first several generations of railways. The first rails, like this one, photographed in Illinois by Timothy O’Sullivan leading to a gold mine, was made of wooden rails. Eventually they added protective iron, steam locomotion by fixed engines and the earliest  commercial steam locomotives. All these came about because of the mines.

commercial steam locomotives. All these came about because of the mines.

The old wooden rails worked very well. Gold carts, or ore cars, were moved up and down the railway using a pulley. The original design of these carts was used in Colorado mines in the late 1800s. The system even had a 360° operating turntable, which allowed the car to dump in any direction. The wheels were exclusive, with a curved five spoke cast iron design. Running the ore carts along the railway wasn’t easy either. There may have been a steam engine to work the pulley later on, but at first, it was all human muscle, and it wasn’t easy.

2 Responses to Mining Innovation