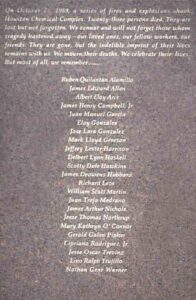

There is really no good reason to ever compromise on the safety procedures in a plant. People often think that it’s not that important to follow every safety procedure, every time…until something goes wrong. Then, they know the purpose of the safety procedures. On October 23, 1989, 23 people lost their lives in a series of explosions sparked by an ethylene leak at a factory in Pasadena, Texas. It was determined that the blasts, which took place at a Phillips Petroleum Company plant, were caused by inadequate safety procedures.

There is really no good reason to ever compromise on the safety procedures in a plant. People often think that it’s not that important to follow every safety procedure, every time…until something goes wrong. Then, they know the purpose of the safety procedures. On October 23, 1989, 23 people lost their lives in a series of explosions sparked by an ethylene leak at a factory in Pasadena, Texas. It was determined that the blasts, which took place at a Phillips Petroleum Company plant, were caused by inadequate safety procedures.

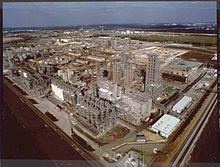

The Phillips 66 Chemical Complex in Pasadena houses a polyethylene reactor that synthesizes essential chemical compounds for plastic production. This facility generates millions of pounds of plastic each day, which are then utilized in manufacturing toys and various containers. Always looking to better their bottom line, Phillips outsourced a significant portion of the plant’s essential maintenance work to reduce expenses. Fish Engineering and Construction, the main subcontractor, already had a less-than-exemplary reputation before the disaster on  October 23rd. Previously, in August, a Fish worker-initiated maintenance on gas piping without isolating it, leading to the release of flammable solvents and gas into a work area. The resulting ignition caused the death of one employee and injuries to four others.

October 23rd. Previously, in August, a Fish worker-initiated maintenance on gas piping without isolating it, leading to the release of flammable solvents and gas into a work area. The resulting ignition caused the death of one employee and injuries to four others.

Then, at 1:05pm, on October 23rd, during maintenance work on the plant’s polyethylene reactor, issues emerged once more. A valve was improperly secured, leading to the release of 85,000 pounds of highly flammable ethylene-isobutane gas into the plant around 1pm. The absence of detectors or warning systems failed to alert anyone of the looming catastrophe. In under two minutes, the vast gas cloud exploded with the force equivalent to two-and-a-half tons of dynamite. The blast was heard for miles in every direction, and the ensuing fireball could be seen from at least 15 miles away. At Phillips, twenty-three workers lost their lives and an additional 130 sustained serious injuries when the initial explosion triggered a series of subsequent explosions.

The initial emergency response came from the Phillips Petroleum Company’s fire brigade, who were quickly supported by the Channel Industries Mutual Aid (CIMA) team. Collaborating governmental entities included the Texas Air Control Board, Harris County Pollution Control, the Federal Aviation Administration (FAA), the US Coast Guard, the Occupational Safety and Health Administration (OSHA), and the US Environmental Protection Agency (EPA).

The initial emergency response came from the Phillips Petroleum Company’s fire brigade, who were quickly supported by the Channel Industries Mutual Aid (CIMA) team. Collaborating governmental entities included the Texas Air Control Board, Harris County Pollution Control, the Federal Aviation Administration (FAA), the US Coast Guard, the Occupational Safety and Health Administration (OSHA), and the US Environmental Protection Agency (EPA).

Investigation of the disaster revealed that despite the Occupational Safety and Health Administration (OSHA) citing Phillips for multiple serious safety violations in the past, a comprehensive inspection of the plant had not been conducted since 1975. Testimonies also uncovered that the plant was susceptible to disaster due to insufficient safety measures during maintenance. Nevertheless, even knowing all that, Phillips and its managers were never required to face criminal charges.

One Response to Phillips 66 Chemical Complex Explosion