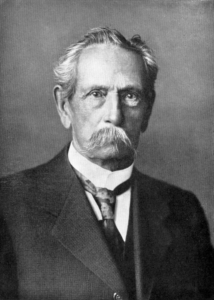

henry ford

In the United States, at least, many of us equate the first car to Henry Ford, but in reality, that is not the case. In fact, the first car wasn’t built in the United States at all. Henry Ford made great strides in the automobile industry, to be sure, but he didn’t start it all. That honor goes to two European engineers, Karl Benz and Emile Levassor. Benz and Levassor created the first automobile in the 19th Century.

In the United States, at least, many of us equate the first car to Henry Ford, but in reality, that is not the case. In fact, the first car wasn’t built in the United States at all. Henry Ford made great strides in the automobile industry, to be sure, but he didn’t start it all. That honor goes to two European engineers, Karl Benz and Emile Levassor. Benz and Levassor created the first automobile in the 19th Century.

Benz patented the first automobile in 1886. It was called the Benz Patent-Motorwagen (meaning “patent motorcar”), and it was actually built in 1885 by Karl Benz. This one is widely regarded as the world’s first production automobile…meaning a self-propelled vehicle for carrying people. I suppose that at the time, the vehicle was considered expensive with an original cost of 600 imperial German marks, which equates to approximately 150 US dollars, or about $4,321 in 2020. Karl Benz applied on January 29, 1886, and the vehicle was awarded the German patent number 37435. Following official procedures, the date of the application  became the patent date for the invention once the patent was granted, which occurred in November of that year. Benz actually unveiled his invention to the public on July 3, 1886, on the Ringstrasse in Mannheim. About 25 Patent-Motorwagen were built between 1886 and 1893. The car is currently being maintained by Mercedes-Benz Classic.

became the patent date for the invention once the patent was granted, which occurred in November of that year. Benz actually unveiled his invention to the public on July 3, 1886, on the Ringstrasse in Mannheim. About 25 Patent-Motorwagen were built between 1886 and 1893. The car is currently being maintained by Mercedes-Benz Classic.

The “car” was really a glorified tricycle…with a motor, of course. It had three wheels that looked much like bicycle wheels. It would not be the kind of car that a person would want to ride in during the winter months. There is no top on the vehicle at all, and of course, no heat. It’s just you and the elements. Still, you could get where you were going faster, at least for that time in history. So, you didn’t have to be out in the elements as long. The car was a little primitive, but it did set a record or two. On August 5, 1888, Karl Benz wife, Bertha was the first person to drive an internal-combustion-

engined automobile over a long distance…about 65 miles. Long for the time, I guess. She was actually field testing the Benz Patent-Motorwagen. They were working on inventing a brake lining and solving several practical issues during the journey. The car did well, and in doing so, she brought the Patent-Motorwagen some worldwide attention and got the company its first sales. It was an amazing day.

engined automobile over a long distance…about 65 miles. Long for the time, I guess. She was actually field testing the Benz Patent-Motorwagen. They were working on inventing a brake lining and solving several practical issues during the journey. The car did well, and in doing so, she brought the Patent-Motorwagen some worldwide attention and got the company its first sales. It was an amazing day.

These days, everyone is fighting for a higher minimum wage, but in may years gone by, people were happy to get what little they were given. The Great Depression was one of those times for sure, but there were others. On January 5, 1914, Henry Ford and his vice president James Couzens absolutely stunned the world when they announced that Ford Motor Company would double its workers’ wages to five dollars a day. Now in this day and age, the workers would just go out and look for another job if that was offered, but back then, they were all going to be rich!! Of course, newspapers around the world were gushing with the great news. The notion of a wealthy industrialist sharing profits with workers on such a scale was unprecedented. Everyone wanted to work for Ford.

These days, everyone is fighting for a higher minimum wage, but in may years gone by, people were happy to get what little they were given. The Great Depression was one of those times for sure, but there were others. On January 5, 1914, Henry Ford and his vice president James Couzens absolutely stunned the world when they announced that Ford Motor Company would double its workers’ wages to five dollars a day. Now in this day and age, the workers would just go out and look for another job if that was offered, but back then, they were all going to be rich!! Of course, newspapers around the world were gushing with the great news. The notion of a wealthy industrialist sharing profits with workers on such a scale was unprecedented. Everyone wanted to work for Ford.

In the century since, many people have theorized that the increased pay was to justify assembly line speed-ups, while others speculated it was to counteract high labor turnover due to increasingly monotonous assembly line work. Those who were fans of Ford called it pure philanthropy. Those who didn’t like Ford called it little more than an elaborate publicity stunt…maybe to gain fame or to brag about his successes, but the truth was likely a little of both. A successful boss should share his successes with those who helped him to achieve the level of success he has gained. Of course, not all do, and my guess is that those who wouldn’t do that are the ones who screamed the loudest. There is no pain in business bigger that when someone does the right thing when you won’t.

In order to really understand why Ford implemented the Five-Dollar Day, one must realize that his advances in the moving assembly line, and experiments through 1913 and into 1914 reduced the time required to build a Model T automobile from 12½ hours to just 93 minutes. Increased efficiencies lowered production costs, which lowered customer prices, which increased demand. The public was eager to buy all of the cars Ford could build. That meant that he needed to increase production, and good help is always hard to find. When you find good workers, you should pay them well. Explosive production gains came at the cost of worker satisfaction. The workers were skilled in their little area of the project, and after a while, doing the same job over and over again can get monotonous. The very goal of the moving assembly line was to take what had been relatively skilled craftwork and reduce it to simple, rote tasks. Workers who had previously taken pride in their skilled labor were quickly bored, and some took to lateness and absenteeism. Many simply quit, and Ford found itself with a crippling labor turnover rate of 370 percent. The assembly line was a great invention, but it was hard on the workers, and the assembly line depended on a steady crew to run it. Training replacements was expensive and time consuming, so Ford decided that a bigger paychecks might make the factory’s tedious labor more tolerable.

The increased wages may have seemed like the best solution, but it backfired in a way. The need to retain workers and the subsequent Five-Dollar Day as an effort to do so, worked too well in the end. Within days of the announcement, thousands of applicants came to Detroit from all over the Midwest. They parked at Ford’s gate, and immediately overwhelmed the company. Riots broke out, and the crowds were turned away with fire hoses in the icy January weather. To overcome the problem, Ford announced that it would only hire workers who had lived in Detroit for at least six months. Finally, the rioting stopped and peace returned to the area. Of course, for those who had jobs at Ford, there was the “fine print” to deal with If you made $2.30 a day under the old pay schedule, for example, you still made that wage under the Five-Dollar plan, but if you met all of the company’s requirements, Ford gave you a bonus of $2.70. I don’t suppose that garnered a lot of good feelings either. Many people couldn’t wrap their minds around the profit-sharing plan. They needed the money now.

Part of Henry Ford’s reasoning behind the Five-Dollar Day was that workers who were troubled by money problems at home would be distracted on the job. If higher pay was intended to eliminate these problems, then Ford would make sure that his employees were using his gift “properly.” The company established a Sociological Department to monitor its employees’ habits beyond the workplace. “To qualify for the pay increase, workers had to abstain from alcohol, not physically abuse their families, not take in boarders, keep their homes clean, and contribute regularly to a savings account. Moral righteousness and prudent saving were all well and good, but they were not generally an employer’s business…at least not outside of working hours. In contrast, Ford Motor Company inspectors came to workers’ homes, asked probing questions, and observed general living conditions. If ‘violations’ were discovered, the inspectors offered advice and pointed the families to resources

offered through the company. Not until these problems were corrected did the employee receive his full bonus.” At this point, I would have to say that the company was taking far too much control. Many others agreed, and by 1921, the Sociological Department was largely dissolved. The Five-Dollar Day was a good idea in the beginning, but in the end, it was one that just got a little out of control.

offered through the company. Not until these problems were corrected did the employee receive his full bonus.” At this point, I would have to say that the company was taking far too much control. Many others agreed, and by 1921, the Sociological Department was largely dissolved. The Five-Dollar Day was a good idea in the beginning, but in the end, it was one that just got a little out of control.

These days, so many things are automated, that we hardly know how to work in an environment that requires us to hand build everything. Machines often make most of the things we buy, but it wasn’t always so. In the beginning of the automobile age, cars had to be put together by hand, making it a very slow process. If you are going to sell mass quantities of something, you have to be able to mass produce it. Selling mass quantities of his now famous, Model T, was exactly what Henry Ford wanted to do. So he came up with a way to move the vehicles from one worker to another. Each worker had a specific part they were to place, before the vehicle moved on down the line. Ford’s dream was to make the automobile available to everyone, not just the rich, who could afford to order the new fangled machines. Of course, most people those days didn’t really think that the automobile would ever amount to much, but as we all know, they were very wrong. The automobile has become an absolute necessity for most people…except maybe some in the bigger cities, where owning a car isn’t really feasible because of parking issues and heavy traffic.

These days, so many things are automated, that we hardly know how to work in an environment that requires us to hand build everything. Machines often make most of the things we buy, but it wasn’t always so. In the beginning of the automobile age, cars had to be put together by hand, making it a very slow process. If you are going to sell mass quantities of something, you have to be able to mass produce it. Selling mass quantities of his now famous, Model T, was exactly what Henry Ford wanted to do. So he came up with a way to move the vehicles from one worker to another. Each worker had a specific part they were to place, before the vehicle moved on down the line. Ford’s dream was to make the automobile available to everyone, not just the rich, who could afford to order the new fangled machines. Of course, most people those days didn’t really think that the automobile would ever amount to much, but as we all know, they were very wrong. The automobile has become an absolute necessity for most people…except maybe some in the bigger cities, where owning a car isn’t really feasible because of parking issues and heavy traffic.

On this day, October 7, 1913, Henry Ford’s entire Highland Park, Michigan automobile factory started running on a continuously moving assembly line where the chassis, which is the automobile’s frame, was assembled using a state of the art, revolutionary industrial technique. A motor and rope pulled the chassis past workers and parts on the factory floor, cutting the man hours required to complete one “Model T” from 12-1/2 hours to six. Within a year, improvements in the assembly line reduced the time required to 93 man minutes…to build a car!! That is just amazing to me. The increase in productivity brought about by Ford’s use of the moving assembly line allowed him to drastically reduce the cost of the Model T. Ford’s goal was to make the car affordable to ordinary consumers. This new process allowed him to realize that goal, and before long, everyone had an automobile.

Since the days of Ford’s antiquated assembly line, automation has vastly improved. These days machines can do so much more that their human counterparts. Of course, that has eliminated more than just a few jobs, but as people have learned to run that equipment, new jobs have opened up. In this world, time doesn’t stand still, and progress waits for no man. You have to learn the new skills as they come along so that you can keep up in this fast paced automated world. Assembly lines have come a long way since those old days, and it’s a good thing, because the automobile is now in very high demand around the world, and people won’t wait very long to get one.

In the early history of airplanes, they were used for things like mail. No one had really considered other uses, or if they did, the idea was far in the future in the minds of most people. Nevertheless, there was one man…William Bushnell Stout, who was an aeronautical engineer. William had previously designed several aircraft using principles similar to, and originally devised by Professor Hugo Junkers, the noted German all-metal aircraft design pioneer. Junkers was one of the mainstays of the German aircraft industry in the years between World War I and World War II. In particular his multi-engined all-metal passenger and freight planes helped establish airlines in Germany as well as all over the world. Stout designed planes using the same principles as Junkers had, but they were pretty much on paper. Then in the early 1920s, Ford Motor Company Henry Ford, along with a group of 19 other investors including his son Edsel, invested in the Stout Metal Airplane Company. Stout, a bold and imaginative salesman, sent a mimeographed form letter to leading manufacturers, asking for $1,000 and telling them, “For your one thousand dollars you will get one definite promise: You will never get your money back.” Stout raised $20,000, including $1,000 each from Edsel and Henry Ford. It’s hard for me to imagine that he would get even one investor, but I guess they figured he was, if nothing else, truthful.

In the early history of airplanes, they were used for things like mail. No one had really considered other uses, or if they did, the idea was far in the future in the minds of most people. Nevertheless, there was one man…William Bushnell Stout, who was an aeronautical engineer. William had previously designed several aircraft using principles similar to, and originally devised by Professor Hugo Junkers, the noted German all-metal aircraft design pioneer. Junkers was one of the mainstays of the German aircraft industry in the years between World War I and World War II. In particular his multi-engined all-metal passenger and freight planes helped establish airlines in Germany as well as all over the world. Stout designed planes using the same principles as Junkers had, but they were pretty much on paper. Then in the early 1920s, Ford Motor Company Henry Ford, along with a group of 19 other investors including his son Edsel, invested in the Stout Metal Airplane Company. Stout, a bold and imaginative salesman, sent a mimeographed form letter to leading manufacturers, asking for $1,000 and telling them, “For your one thousand dollars you will get one definite promise: You will never get your money back.” Stout raised $20,000, including $1,000 each from Edsel and Henry Ford. It’s hard for me to imagine that he would get even one investor, but I guess they figured he was, if nothing else, truthful.

The Ford Motor Company produced the Ford Trimotor in 1927. It was one of the first all-metal airplanes. It was often called the “Tin Goose” or “Flying Washboard.” It was the first plane that was designed to carry passengers rather than mail. Now, I don’t know about you, but the idea of flying in something called the Tin Goose or Flying Washboard, would not bring with it a feeling of confidence in the machine that was suppose to get me to my destination. I have to wonder how many people they were able to get to fly in the plane in those years. The plane was designed to carry twelve people and had three engines. The three engines allowed the plane to fly higher and faster than other airplanes or that time period. The plane could reach speeds of 130 miles per hour. The Ford 4-AT-15 Trimotor monoplane, which was piloted by Berndt Balehen, was first used in the first flight over the South Pole in November if 1929.

The interior of the plane was much like the interior of a passenger car on a train. Like most of the seats of any moving vehicle, design as come a long way, both in comfort and in safety, but at that time, it was state of the art. Now planes like this are a novelty item, that people go to see, because it is something they have never seen before, and may never see again. These days, the Tin Goose flies around the country being that novelty item. Recently it came to Casper, and I really wish I had been able to go see it and take a ride…maybe next time. It would be cool to fly in a Flying Washboard or a Tin Goose.

Henry Ford has long been credited for building the first automobile, but what I find interesting and even a little bit funny, is the fact that in reality, that first vehicle, introduced on this day, June 4, 1896, was called a Quadricycle, and in reality was far more like the modern day 4 wheeler ATV than it was an automobile. When we think of an automobile, even the early models, we think of a vehicle with a top over it, or really an automobile body over it. Such was not the case with Ford’s first design. He was more interested in making a vehicle that ran…and ran fast…than in a way to protect the passengers from the elements. I suppose that since people were used to riding in wagons or carriages, having a cover over the Quadricycle wasn’t the most important thing on the wish list. Of course, when it came to capabilities, the Quadricycle was nothing like the modern day ATV, but then the original cars were not capable of going as fast or as far as the modern day automobiles either.

Henry Ford has long been credited for building the first automobile, but what I find interesting and even a little bit funny, is the fact that in reality, that first vehicle, introduced on this day, June 4, 1896, was called a Quadricycle, and in reality was far more like the modern day 4 wheeler ATV than it was an automobile. When we think of an automobile, even the early models, we think of a vehicle with a top over it, or really an automobile body over it. Such was not the case with Ford’s first design. He was more interested in making a vehicle that ran…and ran fast…than in a way to protect the passengers from the elements. I suppose that since people were used to riding in wagons or carriages, having a cover over the Quadricycle wasn’t the most important thing on the wish list. Of course, when it came to capabilities, the Quadricycle was nothing like the modern day ATV, but then the original cars were not capable of going as fast or as far as the modern day automobiles either.

Henry Ford didn’t start out as an inventor, but was actually working as the chief engineer for the main plant of the Edison Illuminating Company when he began working on the Quadricycle. He was on call at all hours, because they had to ensure that Detroit had electrical service 24 hours a day. His flexible schedule gave Ford the freedom needed to experiment with his pet project, which was building a horseless carriage with a gasoline powered engine. Ford had seen an article on the subject gasoline powered motors in a November 1895 issue of American Machinist magazine, and his obsession with the gasoline engine was born. Then, the following March, another Detroit engineer named Charles King introduced his hand built wooden vehicle with a four cylinder engine, beating Ford out by about three months. His vehicle was able to travel up to five miles per hour, fueling Ford’s desire to build a lighter and faster gasoline powered vehicle.

As great as Ford was at building his Quadricycle, which would travel at speeds of about 20 miles per hour, it is doubtful that Ford could have ever been hailed as a great designer of garages. As he and his crew went to push the Quadricycle out of the back yard shed they had built it in, they discovered that it was too wide to fit through the door. Not willing to wait another minute, Ford grabbed an axe, and smashed the brick wall away to allow the Quadricycle to be pushed out. Then as a friend rode his bicycle down the street to warn the people of the vehicle that was to follow, Ford drive his Quadricycle for the first time. I find it odd that while Charles King actually built that first vehicle, he was never really credited with doing so, and Ford went on to build many of them, and as we all know, to become quite famous doing so.